Universal mains ballast circuit for LEDs

The development of LEDs of sufficient power output and efficiency to be used as sources of illumination is an excellent thing. However, partly because of capitalism and partly because of plain bad thinking, the light sources implemented with them have an unfortunate tendency to be shit.

LED lights are a poor match to capitalism because they potentially last for fucking ever, so having bought them once people don't need to buy them again. This leads to them being fucking expensive and/or being deliberately badly made so they do not in fact last for fucking ever.

Plain bad thinking is manifested in such aspects as the insistence on making LED lights in a shape that resembles an incandescent bulb, which is a shape that makes sense for enclosing an incandescent filament but does not make sense for mounting LEDs and their associated ballast and heatsink, and results in bad design compromises being made to fit the inappropriate shape; and, less obviously, a widespread insistence on thinking of LEDs as voltage-driven devices when in fact they are current-driven, which encourages the use of inappropriately-designed ballasting methods.

Common deficiencies from these causes include the following (it will be seen that these items often exist in conjunction with each other, and also that the list is not exhaustive):

(Of course the "inadequate power" item also tends to persist as a problem because far too many cunts don't care about lights that are too dim to see what you're fucking doing because all they ever do is watch the fucking TV and never fucking read anything or do anything requiring motor/visual coordination. Some of them even install shit dim lights on purpose and call it "mood lighting", yeah, it does get me in a fucking mood and all, I want to fucking see. A typical living room requires at least a 65W fluorescent fitting, preferably two, but instead what happens is cunts install things like candles and think it's great to blunder about in the fucking dark. One of the great things about LEDs is the possibility to at last get a decent amount of light without using a stupid amount of juice to make it.)

The overall result is that with LED lights you have a choice between expensive and shit, or cheap and really shit. This is dead and chewed, so I have been poking around with the concept and devising means of taking what is available cheaply and refreaking it into something that isn't shit. Two types of LED light are described, a low power unit and a high power unit.

Note that these modifications are for use on UK mains, ie. 240V 50Hz. (Yes, it is 240V, not 230V, at least on every supply I've ever measured, even though 230V is supposed to be the EU standard. That EU standard did not offer any opportunity for adding to its implementation 15 other politically unpopular things that the UK government had been wanting to do for ages and then telling the public the lie that all those things were imposed by the EU too, which is how UK governments usually make use of EU directives, so they just played games with the tolerance on the voltage so that it technically complied with the standard while still being nominally 240V, and nobody even noticed.)

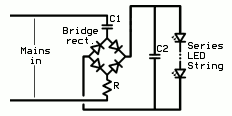

On the right is a "universal" ballast circuit for running LEDs off the mains. Some commercial LED lights do in fact use this circuit, but usually with inappropriate component values; in particular they make C2 too small, which causes flicker and strobing effects. The values should be chosen as follows:

All these components are readily available off ebay; the most "difficult" part is to obtain the LEDs cheaply and in a form that avoids the need to solder together and mount huge numbers of individual LEDs.

This type is not massively bright, but it is fine for the light in the bog or the hallway or something, and of course it is perfectly possible to install them in clusters for more light.

There are many different varieties of "LED tape" available on ebay. As standard, they are all extremely shit, because they use plain resistors for ballasts and waste a quarter of the input energy as heat. However, that is their sole source of shitness, and it is possible to modify them. Some varieties are more easily modified than others.

This modification uses LED tape intended for 12V DC which has parallel groups of 3 series LEDs with one 150 to 180 ohm ballast resistor per group, and 120 LEDs per metre. Similar varieties are available with 60 LEDs per metre but these also give you fewer LEDs per pound. The resistor values are used as an indication of the power-handling capability which is far more trustworthy than whatever made-up figures the listing quotes.

There are also varieties with other groupings of LEDs and other values of ballast resistors. These characteristics are never described in the listing text, so it is necessary to choose from listings that have clear enough photographs to read the resistor markings and count the LEDs per group.

The tape itself is made of conductive copper tracks deposited on a heat-resistant plastic base and covered with a white insulating layer. The reverse side of the tape is coated with adhesive protected with wax paper. The tracks form a bus bar down either edge of the tape, and connect the LEDs into series groups of 3 each with a ballast resistor, all in parallel across the bus bars.

Some varieties use a double-sided tape with copper tracks on both sides, the tracks on the underside being a duplication of the bus bars. These varieties are not suitable as the duplicate bus bars are too wide to be severed without making unwanted cuts to the tracks on the upper surface as well. Again the listing text never tells you about this, so it is necessary to find a listing which includes a photograph showing the reverse side of the tape with the wax paper peeled off so you can see there are no tracks on that side.

The modification is simple, if somewhat tedious:

The photo shows the tape before and after modification, with the electrical path superimposed. It doesn't really look purple; I have messed with the colours to make the conductive tracks stand out more.

No heatsinking is required as the heat generation is distributed along the length of the tape and the thermal power density is low. The tape can be enclosed with eg. transparent PVC tubing to insulate it and this will still only get vaguely warm.

This type is a useful replacement for something like a 40W fluorescent, using less power, giving more light output and improving the ability to see what you're doing.

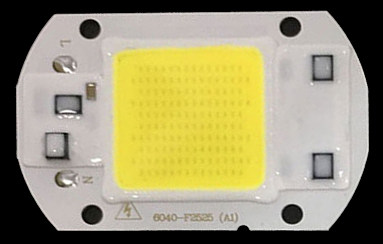

Searching ebay using search terms along the lines of cob led smart ic intelligent driver 220v will bring up numerous listings for devices similar or identical to the photo on the right, which is where that photo came from. They are available in many different shapes, sizes and power ratings. They are intended to be connected directly to the mains without further ado. The caption on the photo is a closer reflection of reality than the titles of the ebay listings.

The ICs are not "smart" at all. They are just high-voltage, low-current semiconductor constant current sources - purely resistive and dissipative. Each one has a fixed output of a few tens of mA and they connect a number of them in parallel to obtain a total current appropriate to the power output. They conduct during the half of each input half-cycle when the voltage is above 240V, dropping between 0 and 100V to keep the current constant. This dissipates around 20% of the input power as heat. This heat is dumped into the same chunk of aluminium that the LEDs are mounted on. They're not "smart" or "intelligent" at all; they are inefficient, wasteful, and shite. They are, in short, a pile of arse, so I refer to them as arse chips for convenience.

Most of these plaques seem to be constructed around a "basic unit" of 72 high power LED chips in series, with the power determined by the number of arse chips per unit. So as the power rating increases, the LED chips are driven, and then overdriven, progressively harder, and the overall thermal power density goes up as well. Once this process reaches a limit they make even higher power plaques by adding more basic units in parallel and starting the process again. The larger plaques can catch fire after only a few thousand hours of operation.

The smaller end of the range covers the power range from 20 to 50 watts, in a plaque comprising one 72-LED basic unit and two to five arse chips. This is cruelty to LEDs at the higher powers, but they are suitable for kind conversion to 25W lights with an efficient ballast.

On the right are two views of the 30W version with the white silicone gunk scraped off, fiddled with to emphasise the relevant features and annotated with the circuit layout and labels for the important parts. Because the LEDs are already connected in a series string of 72, the conversion to a non-shit light is quite simple:

Note that although the conductors we are soldering to are ordinary copper PCB tracks, because they are mounted on an aluminium backplate it is a sod to solder to them. At least a 60W iron is needed, and the soldering should be completed before attaching the plaque to the heatsink.

A 3mm x 200cm2 aluminium plate is a sight cheaper than an actual formed heatsink of equivalent surface area, especially if you get it from a supplier of offcuts. This size of heatsink does get hot, but not too hot to hold (mind you, I do sometimes get accused of having asbestos fingers); since, excepting a few exotic thermophilic organisms, biological systems are much more sensitive to heat than electronic ones, this can be taken as a good indication that the temperature is not excessive. The thickness of 3mm gives enough thermal conductivity to keep the temperature pretty uniform over the whole area and thus make the best use of the convecting area. It does, of course, need reasonably decent natural air circulation around it. Crappy circulation requires a proportionately larger heatsink.

Postscript: Some utter bell on the internet thinks that LED lights should be built using computer fans (run at a low enough speed to be inaudible) for forced convection instead of making the heatsink big enough for natural convection to do the trick. This would, obviously, produce an LED light that was fine when it was new but nevertheless cooked itself after only a fraction of its potential lifetime. Either the air passages would block up with dust sucked in by the fan or the fan bearings would dry out and it would seize up. Seized fans and blocked heatsinks are the most common course of PC hardware failures, even though most PCs are changed for a bigger one after a much shorter time than the potential life of an LED light. Yet this divot denies the unreliability using the utterly specious logic that the internet runs on computers with fans in them, and the internet is reliable, therefore computer fans are reliable... which is, of course, bollocks.

Back to Pigeon's Nest

Be kind to pigeons