The Lighter Lighter

Lighters are shit.

There are 2 types of lighters (excluding the ones you can't refill, which are simply too shit to be worth considering, because you can't refill them; and also excluding the ones which are fuelled not by liquefied butane gas but by some blend of C9-ish hydrocarbons which are liquid at STP, which are smelly fuckers with an interesting but somewhat dodgy thermal runaway behaviour, and so are also shit, and nobody seems to sell them anyway)... er... shall we start that again?

There are 2 types of lighters. One is the kind with a piezoelectric spark generator as an igniter. These are OK to begin with but they metamorphose into turds over a period of a few months (or sometimes a couple of weeks, if you're unlucky). The spark gets imperceptibly weaker and weaker and the probability of ignition declines from nearly 1 to barely more than zero, so you go from clicking it once to clicking it again and again and again until you have to give your thumb a rest before having another shot, and when it finally does light you've got so much into the groove of repeatedly clicking it that you can't stop clicking in time and you let it go out again before you can help yourself and have to start all over again. This is obviously shit, and what makes it even more shit is that there is plainly gas coming out and there is plainly still a spark which looks perfectly decent to the eye, so the thing fucking well ought to fucking ignite and why the fuck doesn't it. And in the end you have to buy another one after only a few months when if it hadn't been shit it ought to have lasted longer than you would, which of course is why they make them shit in the first place, which indicates that they are wankers and provides a minor but commonplace demonstration of how capitalism is shit.

The other type is the Clipper pattern with a flint-and-wheel igniter. These are partly shit to begin with and metamorphose into big sloppy turds over a period of a few months.

The partial shitness is inherent and derives from two causes. The obvious cause is that they depend on flints, which wear out, and cause the lighter to suddenly and completely stop working at entirely unexpected moments. This is really fucking annoying because all of a sudden without any warning you haven't got a light. And there isn't anywhere on the lighter you can stash a spare flint to cover for such emergencies, which makes it even more annoying.

The less obvious cause is that the design of the fucking things is fundamentally wrong. With the shape of the various parts being what it is, there is no way to release the gas before producing the spark (unless you use both hands, and it's still awkward). The sequence of events is forced to occur the wrong way round, with the spark happening before there is any gas coming out for it to ignite. They rely on the flint producing enough of a fwoosh that some of the burning crap hangs around long enough to still be there when the gas does come out. But it only actually does that reliably for the first few activations of a brand new lighter, and after that the design deficiency acts to increase the sloppiness of the turd the thing is metamorphosing into. Which leads us to the further aspects of shittiness which are revealed in the course of the metamorphosis.

The spring that provides the pressure on the flint is too short, so the spring force diminishes significantly as the flint gets used up. If it is enough to produce a decent spark with a new flint, it ends up being far too weak with a worn one, so the flint barely strokes the wheel and next to fuck all happens. If you try and fix the problem by stretching the spring a bit, it then does work with a worn flint but with a new one there is so much friction on the wheel that you can barely move the fucking thing. So either way you can't win.

There's no reason why the things couldn't be made with a long spring that goes all the way down to the bottom of the lighter, which would give a significantly more constant force, but they fucking aren't, and the way they are made you can't even modify them to take a longer spring without puncturing the gas compartment.

It also doesn't help that sometimes the springs themselves are shit, and aren't tempered properly, so the force for a given degree of compression gets smaller and smaller as time goes by until the thing is basically fucking useless. And you can't in this case help matters by stretching it a bit because the temper is gone and as soon as you reassemble the igniter the effect of your stretching gets reversed.

The wheels are also shit. Again they are shit in multiple ways some of which are quicker to manifest than others. The most obvious way is that they accumulate a kind of paste made of grease and dead skin off your thumb, which acts as a lubricant and buggers up their ability to make a spark. Of course you can try and clean it off, but it gets deep into all the little grooves and you can never get rid of all of it, so you end up having to clean it more and more often and with less and less effect. The paste is also the same colour as the wheel, so you can't see what you're bloody doing, which also doesn't help.

Then, they go blunt. They are made of shit metal which isn't hard enough, and the edges of the teeth on them get worn blunt, so instead of scraping off big enough particles of cerium alloy to make a decent long-lasting spark, they just kind of rub off traces of it which light up a bit but because the shitty design hasn't yet released any gas at that point it doesn't do any good. Of course there is fuck all you can do to fix this because how the fuck do you sharpen something that shape and size.

And they are not properly designed for your thumb to rotate them. The two driving surface bits on either side of the abrasive wheel part are much too small a diameter, not much larger than that of the abrasive wheel itself, so there isn't an adequate mechanical advantage to rotate the wheel against the friction without the need to apply excessive force. There is no reason why they couldn't be made with a considerably larger diameter relative to the abrasive part, but they aren't, because they are shit. And the measures they take to make it more or less possible for your thumb to apply the excessive rotational force required are also shit. You get sharp-edged knurling, for instance; or you get a kind of pentagonal cycloidy shape, with five points sticking out; or you get some other pathetic attempt at trying to improve the mechanical coupling - they seem to change it every so often, but they only ever change it to some other kind of shitty bodge, and never address the fundamental problem that the fucking diameter is too fucking small so you have to apply too much force in the first place.

Again this gives tolerable results when the lighter is brand new but is fucking shite when it's been used a bit. Because as the thing gets less and less able to produce a useful spark, you have to flick it more and more times to make it light, and the bastarding thing starts taking the skin off your thumb. Eventually you have to use the other hand because your thumb is too sore to do it any more.

After the thing has been used a bit more it gets even worse. The amount of spark produced gets so crap that it simply isn't possible to continue to go along with the fucking stupid design that doesn't release the gas until after making the spark. Instead you have to grow one thumbnail long enough to hold the valve down using that thumbnail and then try and flick the wheel with one finger of the other hand. This is a pain in the fucking arse because everything gets in the way of everything else. It's not possible to flick the wheel either forcefully enough or fast enough using a finger of the other hand, and if you do try you tend to end up knocking your thumb off the valve so it doesn't do any good anyway. It's hard to make it produce any kind of spark at all doing it like that, so instead of a sore thumb you end up with a sore finger, but at least you've got more spare fingers to use instead.

Basically the whole thing is a load of fucking shite because the design and materials alterations necessary to make either type of lighter last longer than the person who buys it are ridiculously trivial and if it cost as much as one penny per lighter extra to make them like that I'd be surprised. So they fucking well ought to fucking well do it. That way everyone would only ever have to buy one lighter and they would only need to make enough new lighters to provide for new people coming along and lighters that got lost or broken. But instead they deliberately make them shit so the same person has to keep buying lighters again and again, so they have to keep making lots of them, so there is that constant stream of materials coming out of the ground and passing through a factory and then a person and then going back into the ground in a fucked and useless condition, and all the extra work involved in making that happen, because capitalism is all about burning entropy and being a cunt.

So anyway I got sick to the fucking bollocks of buying lighters and buying fucking lighters and repeatedly having to spend money buying something which I already knew was shit. So I made a lighter lighter.

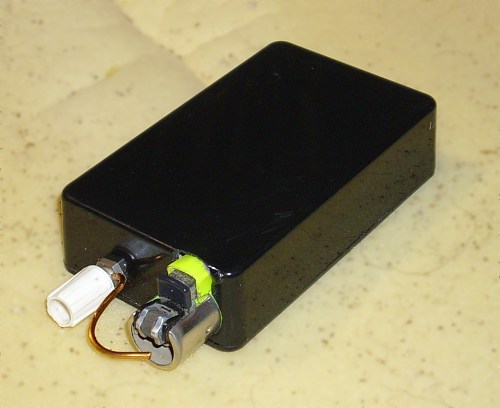

What we have here is basically a high voltage generator that steps up the 3.7V or so from a lithium cell to several kilovolts to produce a continuous stream of sparks. The lighter is free to move up and down in its compartment, and the bottom of the lighter rests against a spring (extracted from the piezoelectric ignition mechanism of another fucked lighter), which is quite a bit stronger than the return spring on the lighter's gas valve. So as you press your thumb down on the gas valve, the valve opens before the spring is compressed very much. As you apply more force, the spring compresses further and the lighter moves downwards far enough to operate a microswitch, which supplies power to the high voltage generator. This produces a stream of sparks between the big bendy electrode and the metal shroud around the top of the lighter, which ignites the gas. You can then back off the force a bit and allow the spring to push the lighter back upwards and release the microswitch, stopping the sparks, while still applying plenty of force to the weaker spring of the gas valve to keep the gas valve open.

To enable the lighter to be refilled, the screw terminal post can be loosened and the big bendy electrode swung aside so the lighter can be taken out. (With the lighter removed of course the high voltage generator cannot be activated, as there is nothing to press on the microswitch.) The lithium cell can be recharged via a socket in the bottom of the case.

The circuit is very simple and is basically the same as the high voltage part of a capacitive discharge electronic ignition system for a car. A primary inverter charges a 2μF capacitor to 300V, at which voltage a gas-discharge breakover device conducts and discharges the capacitor through the primary of the secondary transformer, producing a pulse of nominally 15kV on the transformer secondary which is applied to the spark gap.

The primary inverter is a sort of cross between a blocking oscillator and a Hartley oscillator, with drive applied to the emitter as well as the base. This improves the switch-off speed of the transistor and reduces the switching losses, which are the major source of loss. The resonating capacitor across the feedback winding does not affect the operating frequency - when the transistor is on the Q hits the deck and any resonance is killed - but it does have some further effect in improving the switching speed, which is of the same order as the rise time of the nominal 17MHz or so resonant frequency. The operating frequency is a function of the supply voltage, the transistor's hFE, the winding inductances, and the instantaneous voltage on the output capacitor, so it isn't constant, but it is in the hundreds of kHz range.

The BD441 transistor was selected for adequate collector voltage and current capacity, good gain and speed, and availability. The connection of the low voltage end of the secondary winding to the transistor collector, rather than to ground, is important for the purpose of eating the switch-off spikes on the collector to keep within its rating. The BYV26C diode was selected for high switching speed, voltage rating, and availability. Use of a high speed diode is important given the hundreds-of-kHz operating frequency.

The transformer for the primary inverter was made out of a Chinese toroidal inductor described as "47μH 3A" and nothing else, which I got in a bag off ebay or amazon for 10p a pop. It was originally wound with 32 turns. I took half of them off, leaving a 16-turn winding of nominally 12μH occupying half the circumference of the core to use as the primary winding, and used the bit of spare wire to wind a 4-turn centre tapped winding for the feedback winding over the top of it. The secondary winding was made using a length of 0.2mm wire 8 times the length of the bit of wire I took off (with a scrap of ordinary wire temporarily soldered to the end to make it easier to poke through the hole), covering the half of the core left unoccupied by having taken it off. This of course does not give exactly 8 times the number of turns, because it's different diameter wire in more than one layer, but it doesn't matter.

The output capacitor is two 1μF 630V mylar film capacitors in parallel. Polyprop would be better but it's gilding the lily a bit for a thing like this, and anyway I have a big bag of the mylar ones.

To find a suitable 300V gas discharge breakover device it is necessary to search for "gas discharge tube" (or "GDT"). This is fucking stupid because of course a fluorescent lamp is also a gas discharge tube, and so is the starter for it, and so is a neon indicator, and so is a voltage-regulator valve, and so are fuck loads of other things which are nothing like the things intended for voltage surge suppression which are what we want, so why the fuck they don't call them gas discharge breakover devices or gas discharge surge suppressors or some other name which means just those and not thousands of completely different things as well I have no bloody idea, but they don't.

The secondary transformer was a bit of a "guess-and-by-God" construction, but thank you Lord, it works. It is made using a 30mm long, 5mm diameter ferrite rod which originally had 10 turns of 1.6mm wire wound on it as a high current inductor in a computer PSU. I took that off and wrapped the rod in a layer of plastic, because you apparently can't rely on ferrite being an insulator when you have multiple kilovolts floating about and I have been caught out before doing this sort of thing with the high voltage managing to flash over through the ferrite. I then put about 700 turns of 0.2mm wire on it, in multiple layers with another layer of plastic between each one. They were supposed to be neat layers with all the turns lying regularly alongside each other, but minor irregularities due to things like the wire turning out to be kinked on the reel or not being able to get all the creases out of the layer of plastic tend to be repeated in negative form in the next layer up, rather than just washing out, so the anomalies accumulate layer by layer and the last layer was really rather disappointing. I didn't count the turns, so the number is half accurate and half a guess, based on number of layers times length of winding per layer divided by wire diameter and then knock off a chunk to compensate for it not being neat. The layers of plastic are considerably longer than the windings to guard against flashovers round the ends. I finished off with another layer of plastic and then put 14 turns of ordinary plastic-insulated single strand wire of 1.6mm overall diameter over the top for the primary winding. I haven't bothered trying to measure the inductance, but I'm guessing that the original inductor in the PSU would have been in the low tens of μH so the primary is probably something about the same (and the secondary 2500 times bigger).

The plastic used for the insulating layers was that blue shit you sometimes get parcels or the things inside them wrapped in, which is a bit like cling film but it's thicker and it has some kind of actual adhesive layer on one side of it, albeit very feeble, instead of just relying on electrostatic clinginess like you do with your sandwiches. I used this because I have a sodding great big roll of it, and it seems to be basically polythene (or possibly polyprop) so its electrical qualities ought to be half decent.

I originally thought that it would be a great idea to use the plastic of the packets the tobacco I use the lighter to smoke comes in. It's pretty tough for its thickness and looks like it ought to make a robust barrier that would wash out irregularities on layers beneath and not get creases, and provide a good surface for the next layer to sit on. It turns out it's shit because what seems to be a single thickness of plastic is actually at least five layers and one of them is made of fucking aluminium, even though there aren't any shiny bits on the package artwork. So you have this conductive pain in the arse running through the whole thing which is at the same potential at both ends of the winding, and the enamel breaks down and it flashes over to the edge of the plastic. (Which incidentally vaporises some of the aluminium and blows it out from inside the plastic into contact with the oxygen of the atmosphere, whereupon it reacts enthusiastically and transforms a comparatively small spark into a great big bloody loud one.) So that stuff is no good, although it does suggest there could be some use for it in making high voltage capacitors perhaps.

The heavy gauge wire removed from the ferrite rod came in handy for making the big bendy electrode. The other end of the transformer secondary is connected to a wee strip of springy brass which makes contact with the metal shroud around the end of the lighter.

The mechanical construction makes heavy use of usefully-shaped pieces of ABS hacked from the casing of a dead scanner, fixed in place in the ABS box by means of the glue for joining ABS plumbing, which is wonderful stuff.

Anyway, it works, look. Interesting to see how the spark moves around the rim of the top of the lighter as the uneven combustion renders different parts of the flame momentarily more conductive. If you hold a neon indicator with the leads poking into the combustion zone, it lights up when the flame ignites. I could make use of that phenomenon to make it turn itself off as soon as the flame ignites, if I could be arsed.

After using the device for a while, I found the spark repetition rate was noticeably increasing. Then the sparks got more and more feeble until it stopped sparking at all. Of course my first thought was to charge the battery, but that didn't sort it, so I took it apart and found the gas discharge breakover device had failed - it was striking at some much lower voltage than 300V, and was then conducting continuously instead of turning off after discharging the capacitor.

So I replaced it, and everything was fine again. But after another month or two it became apparent that the same thing was beginning to happen again. It seems that these gas discharge breakover devices do not like this kind of repetitive operation, and probably grow spikes on the electrodes or something of the kind until the striking voltage becomes unfeasibly low. This is a bit unexpected since although the datasheet indeed rates them for only 100 operations, it's talking about 100 fucking high energy operations; they are used as protection devices to dump fault energy in the hope that only a few components will blow up instead of the entire apparatus, and it's likely that if that does happen they will be replaced themselves as well as a matter of routine. So you'd think with this kind of low power use they'd not even notice anything was happening, and so last for ever. Only it turns out they don't.

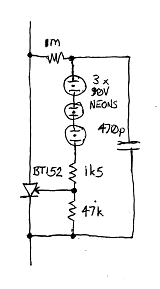

So this time round I replaced it with an extra little board on which were 3 ordinary 90V neons in series, to give a striking voltage hopefully around 270V, arranged to discharge a subsidiary 470pF capacitor into the gate of a thyristor which then discharged the main capacitor into the EHT transformer. It was arranged as a two-terminal device so it just drops straight in in place of the gas discharge device, although I did also find that I had to put a 120 ohm resistor in series with the rectifier diode to make sure the thyristor turned off after each discharge. The BT152 thyristor is a pretty beefy device, and the energy going through the neons is so low they barely light up, so hopefully this version of the trigger device should survive a bit better.

Back to Pigeon's Nest

Be kind to pigeons