Hydrostatic transmission for road vehicles has low losses at high speeds

This is an article from "Design Engineering" magazine, November 1989 issue. The system it

describes is most interesting, but unfortunately doesn't seem to be in development or

production anywhere now as far as I can find out.

Note: If you were looking for information on hydraulic brakes, see

Howard's article How Car Brakes Work.

Article begins

Hydrostatic transmission for road vehicles

has low losses at high speeds

Variable displacement hydrostatic machines offer solutions to the

problems encountered in vehicle transmission systems. Research at

the University of Edinburgh, described by M J Rea and S H

Salter of the Department of Mechanical Engineering, has

centred on improving the efficiency and reducing the noise of axial

piston hydraulic machines.

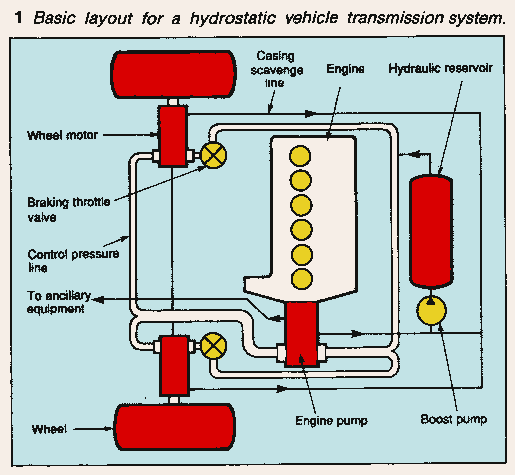

The basic layout for a hydrostatic vehicle transmission is shown in

Fig 1. The engine is directly connected to a variable displacement pump.

Hydraulic pipes connect the pump to two or more variable displacement

wheel motors. A pressurised reservoir allows for temperature expansion and

make-up of leakage. The throttle valves are used to provide hydraulic

braking.

The principal advantage of the system is the infinitely-variable

transmission-ratio between the engine and the wheels. This enables the engine

design to be optimised for maximum fuel economy and attention to exhaust

emissions rather than the emphasis on a smooth torque against speed characteristic.

It becomes possible for the transmission system rather than the

carburettor throttle to be used as the primary way of controlling the engine power.

The engine of an accelerating hydrostatic vehicle would be able to rotate at

peak power continuously while the transmission adjusted the wheel

torque. At the cruising speed, the transmission would force the engine to

a lower speed and so lower the power developed.

Other advantages over mechanical systems are that hydraulic power is

carried in pipes so there are few restrictions to the relative

orientation of the engine and wheel motors. This

Ieaves the vehicle designer more freedom to position the major components.

Power steering and a hydraulic suspension system could be

run directly from the main system. Extra wheel motors could provide four

wheel drive. A regenerative braking system is dependent on an efficient

infinitely variable gearbox. An additional pump/motor connected into the

hydraulics and driving an energy store flywheel would provide dramatic

acceleration and improve urban fuel economy.

Sizing hydraulic transmission components

A system such as that shown in Fig 1 should be designed to deliver maximum

power to the wheels over as large a range of speeds as possible. The power

throughput is the product of the

pressure and the flow. The ratio of the speeds of pump and the motor would

be equal to the ratio of their displacements.

An efficient transmission system on a vehicle requires careful sizing

of the various hydraulic components. The engine-pump would be matched to

develop maximum pressure and flow at the engine's maximum power. The

wheel motor is required to deliver full power over a broad range of

speeds. To avoid over-sizing this means that it is necessary for the

machine to be able to run over the rated speed at reduced stroke. The

motor size required for a particular vehicle would be determined

by the full pressure full stroke torque required at low vehicle speeds and its

capacity to run over the rated speed.

Hydraulic machines have high internal loads opposed by large bearings and are

not designed to run in overspeed conditions. Manufacturers advise that the

pressures be reduced as well as stroke causing the power to drop below rated

peak. The Clerk machine developed at the University of Edinburgh has been

specifically designed to run at three times the rated speed for use in

hydrostatic transmissions.

Losses in hydraulic machines

A hydrostatic transmission involves conversion of power between mechanical

energy and hydraulic pressure. The overall system efficiency is the

product of the efficiencies of the pump and the motor. Pumps and motors with

conversion efficiencies of 90% will lead to a transmission system

losing a fifth of its power throughput. For a successful vehicle

transmission system it is not tolerable to have an individual machine

with losses higher than 5% of throughput.

Trilink pump

The research team built an experimental hydraulic machine based on a

design by Robert Clerk to investigate ways of reducing losses. Fig 2

shows a cross-section of the machine. The principal improvements over existing

designs are as follows.

The Trilink machine makes extensive use of hydrostatic bearings. In a

hydraulic machine the principal loads are due to oil pressure acting on

components. It is possible to oppose a load with a hydrostatic bearing of

Iarger area fed by the pressure that causes the initial load.

The impedances give the bearings stiffness and set the running clearances.

All moving parts are supported on hydrostatic bearings with the

exception of the little ends and Trilink bearings that have limited excursions

and alternating loads so they can be supported by spherical squeeze film

bearings.

The geometry of individual bearings involves a design compromise between

Iow shear losses or low leakage losses. A computer model was used to minimise

the combined shear and leakage Iosses at the machines operating speed.

Large hydrostatic bearings require surfaces that remain flat to within

10-20 microns despite varying loads and temperatures. The research team developed

a number of locating techniques for permitting the bearing support

structure to distort while the running surfaces stayed within tolerances. As

aIl bearings are actively fed the casing is pumped dry of oil so the

machine has no churning loss.

Torque to the swash-plate is carried

by a mechanism known as the Trilink. The swash-plate is coupled to the

mainshaft by three spherically ended links that cary all of the torsional

Ioads, Fig 3. Conventional slipper-pad pumps transmit torque through the

hydraulic pistons.The resulting friction as the piston is forced against the

cylinder wall is a major cause of power loss and wear. The Trilink allows the

Clerk machine to run at larger angles

and higher pressures so having a greater power throughput than conventional

machines of the same size and weight.

Oil has a finite bulk modulus. It is convenient to consider it as

storing the equivalent of around 1% of the pumped energy at 200 bar.

While 500W on a machine developing 50kW is not a great loss in terms

of efficiency it is very significant if even a fraction is dissipated

as noise.The Clerk machine has adjustable port face timing that enables

continuous equalisation between the pressure in the port and the cylinder

whilst the machine is running.

Many hydraulic machines require

high boost pressures to overcome the static head losses caused by oil

circulation in restricted passageways. Breathing losses increase with the

cube of velocity so can become very significant when a hydraulic machine

runs over the rated speed. The primary oil circulation was designed to avoid

abrupt changes in direction and create a hydraulically smooth flow for

the oil passing through the machine.

The machine was tested to investigate the shear lossesat high speed. The shear

losses amounted to 6kW corresponding to 1.6% losses at full pressure power.

Leakage from the hydrostatic bearings was measured and found to correspond well

with the theoretical model, amounting to less than the shear

losses.

Table 1 gives examples of automotive power machines in comparison to the

machine tested at the University.

The Clerk Trilink pump offers a

significant improvement in the performance of axial piston hydraulic

machines. Extensive use of hydrostatic bearings permits the machine to

run at three times the rated speed, so making it ideal for hydrostatic

transmissions. The use of a controllable transmission system would

have a dramatic effect on fuel economy and vehicle

performance.

Acknowledgements

The work carried out at the University of Edinburgh was supported by SERC,

Commercial Hydraulics and Mac Taggart Scott. The project requires

further commercial support to continue the test programme. This paper will be

presented to the AutoTech Congress, 14-17 November at the NEC

Birmingham. Full details of the Congress from Julie Brown, IMechE,

Tel. 01-2227899.

Article ends

Back to Pigeon's Nest

Be kind to pigeons